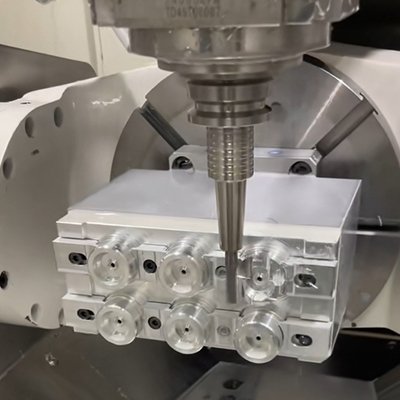

CNC Milling Service

Equipped with 3-axis, 4-axis, and 5-axis machinery, we offer the flexibility to match the most suitable equipment to your product’s specific structure and requirements, ensuring optimal precision and efficiency for every project.

- DFM analysis

- Tight tolerance ±0.01mm

- Delivery in as fast as 3 days

What is CNC milling?

CNC milling is a precise manufacturing process that uses computer-controlled machine tools to remove material from a workpiece, creating complex shapes and features. It involves rotating cutting tools that carve into the material in various directions, allowing for the production of parts with high accuracy and intricate details. This versatility makes CNC milling a popular choice for creating components across various industries.

3 to 5-Axis CNC Milling Service

No matter the structure and requirements of your product, we can match you with the most suitable CNC milling machine, ensuring your needs are precisely met from every angle.

3-axis

It's particularly beneficial for projects requiring intricate details on one plane, enabling rapid iteration and optimization of designs without sacrificing quality or precision.

3+2 axis

At creating parts with complex shapes and features beyond 3-axis limits, enabling machining around a single axis without manual repositioning of the workpiece.

5-axis

For components featuring extremely complex structures and demanding high geometric tolerances, a 5-axis machine tool undeniably stands as the optimal selection.

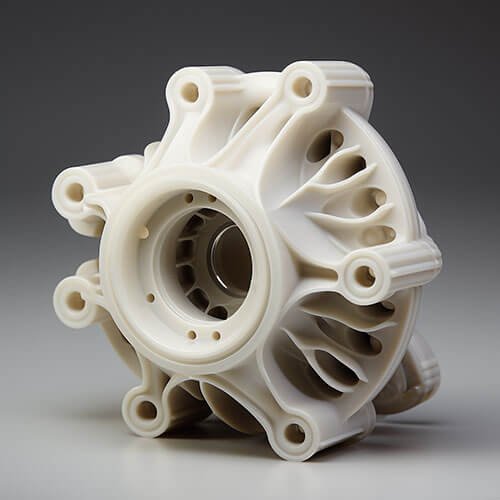

Gallery of CNC Milling Parts

Dive into our showcase of bespoke CNC milling parts, meticulously crafted for our diverse clientele.

Why Choose Neuvance's CNC Milling Service?

An experienced and professional team

Our seasoned team guarantees precision and innovation, transforming your concepts into quality products. Their expertise ensures your projects exceed expectations.

Instant Quote & DFM Analysis

Get fast quotes and DFM analyses, accelerating your project from idea to reality. Our expertise ensures cost-effective and viable designs, driving your project's success.

Fast and Reliable Delivery

Benefit from our swift and reliable delivery, keeping your projects on schedule. Our service ensures efficiency and a competitive advantage.

Advanced Technological Tools

Our advanced equipment guarantees precision and quality, speeding up production to deliver top-notch results efficiently.

CNC Milling Materials

With over 35 materials available for CNC machining, we meet diverse project needs with optimal quality and functionality.

Aluminum alloys are celebrated for their lightweight, strong, and corrosion-resistant properties, making them ideal for a wide range of applications across industries.

Common Grades

Aluminum 7075 | Aluminum 6061 | Aluminum 6082 | Aluminum 6060 | Aluminum 5052 | Aluminum 6063 | Aluminum 5083 | Aluminum 2024

Copper is renowned for its excellent electrical and thermal conductivity, making it a key material in electrical wiring and heat exchangers.

Common Grades

Copper C101 | Copper C110

Brass is valued for its corrosion resistance, machinability, and appealing aesthetic finish, making it a preferred choice for decorative and functional applications alike.

Common Grades

Brass Cz121| Brass C360

Stainless steel is celebrated for its exceptional corrosion resistance, durability, and hygiene, making it indispensable in environments demanding cleanliness and longevity.

Common Grades

Stainless steel 416 | Stainless steel 15-5 | Stainless steel 301 | Stainless steel 440C | Stainless steel 304/304L | Stainless Steel 17-4 PH |Stainless steel 303 |Stainless steel 316/316L

Titanium alloy boasts an outstanding strength-to-weight ratio and superior corrosion resistance, making it ideal for aerospace, medical implants, and high-performance applications.

Common Grades

Titanium Grade 5 | Titanium Grade 2 | Titanium Grade 1

Plastics offer remarkable versatility, lightweight, and cost-effectiveness, alongside a wide range of physical properties tailored to diverse applications.

POM (Delrin/Acetal) | Nylon | PPSU | ABS | PEEK | PTFE (Teflon) | Polycarbonate | Polyethylene | PVC | PMMA (Acrylic) | PET | Polypropylene | G-10 | FR4 | FR4

CNC Milling Surface Finishes

Surface finishes not only bestow products with an aesthetically pleasing appearance but also enhance their functionality with attributes such as wear resistance. This dual benefit ensures that products not only look exceptional but also meet rigorous performance standards.

Nickel Plating

Zinc Plating

Chromium Plating

As Machined

Polishing

Bead Blasting

CNC Milling Tolerances

In instances of special client requests, general tolerances adhere to ISO 2768-m standards. However, when tolerances are specifically noted on the client’s drawings, those specifications take precedence and will be executed accordingly.

Linear Dimensions

| Basic Size Range | f (fine) | m (medium) | c (coarse) | v (very voarse) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | N/A |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over 2000 up to 4000 | N/A | ±2.0 | ±4.0 | ±8.0 |

External Radius and Chamfer Heights

| Basic Size Range | f (fine) | m (medium) | c (coarse) | v (very voarse) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

Angular Dimensions

| Basic Size Range | f (fine) | m (medium) | c (coarse) | v (very voarse) |

|---|---|---|---|---|

| up to 10 | ±1° | ±1° | ±1°30' | ±3° |

| over 10 up to 50 | ±0°30' | ±0°30' | ±1° | ±2° |

| over 50 up to 120 | ±0°20' | ±0°20' | ±0°30' | ±1° |

| over 120 up to 400 | ±0°10' | ±0°10' | ±0°15' | ±0°30' |

| over 400 | ±0°5' | ±0°5' | ±0°10' | ±0°20' |

Straightness and Flatness

| Basic Size Range | H | K | L |

|---|---|---|---|

| up to 10 | 0.02 | 0.05 | 0.1 |

| over 10 up to 30 | 0.05 | 0.1 | 0.2 |

| over 30 up to 100 | 0.1 | 0.2 | 0.4 |

| over 100 up to 300 | 0.2 | 0.4 | 0.8 |

| over 300 up to 1000 | 0.3 | 0.6 | 1.2 |

| over 1000 up to 3000 | 0.4 | 0.8 | 1.6 |

Our Service Process

Uploade Your File

Use our 'Contact Us' form to send us your CAD files and specify the quantity needed for your project.

Get Guote

We typically respond within 24 hours with a quote and provide DFM analysis if necessary.

Commence Production

Upon receiving your order, we promptly schedule production to meet your requirements.

Arrange for Shipment

Based on the specifications of your goods, we arrange suitable packaging and dispatch your order.

CNC Milling Applications

Rapid Prototyping

At Neuvance, our selection of cost-efficient materials, including aluminum 6061 and versatile plastics such as acetal and ABS, paired with the swift expertise of our machinists, elevates our CNC machining services to a premier choice for rapid prototyping.

Rapid Tooling

Given its capability to precisely shape a wide range of robust materials, such as aluminum 5052 and stainless steel, CNC machining is excellently suited for producing durable fixtures or molds.

End-use Parts

CNC machining is ideal for end-use parts because of its high precision and ability to handle diverse materials. Its repeatability ensures consistent quality, making it perfect for producing detailed, complex components.

Testimony

Client Testimony

What Our Client Say?

Positive feedback from our customers is our best endorsement.