“What Is CNC Machining? A Beginner’s Guide” – Here’s everything you need to get started with CNC!

Understanding the Basics of CNC Machining

CNC machining is a vital element in contemporary manufacturing, enabling the conversion of digital blueprints into tangible products. This technology operates on the principle of Computer Numerical Control (CNC), where automated machines precisely execute computer-generated designs.

At the core of these systems lie essential components such as controllers, spindle motors, and feedback sensors. These elements work in harmony to fabricate detailed components with remarkable accuracy, transforming digital concepts into physical realities.

The History of CNC Machining

The origins of CNC machining can be traced back to the period following World War II, marking the beginning of a new era in industrial manufacturing. During this transformative time, what began as basic automated systems gradually evolved into highly sophisticated machines capable of performing intricate tasks with little human oversight.

Key innovations played pivotal roles in this revolution. The introduction of microprocessors and the development of Computer-Aided Design (CAD) software fundamentally altered the manufacturing sector, driving it towards unprecedented efficiency and precision.

Types of CNC Machines

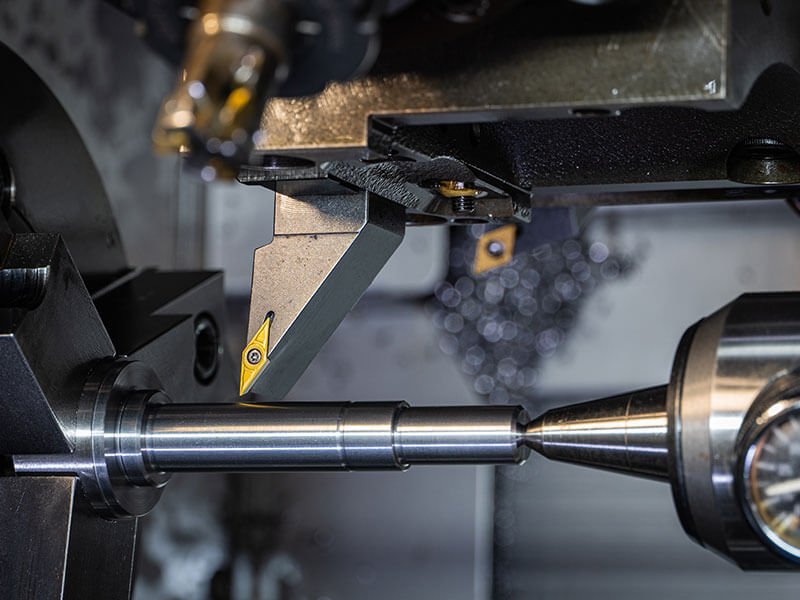

The world of CNC machinery is vast and varied, with each type designed for particular tasks. Mills, for instance, employ rotary cutting tools to shape material, whereas lathes spin the workpiece against a fixed cutting device for cylindrical shaping. Routers excel in carving softer materials and detailed patterns.

Adding to these fundamental machines, there are specialty CNC machines like laser cutters and plasma cutters. These advanced machines utilize high-energy beams to cut through materials, achieving precision that traditional methods cannot match, thus broadening the capabilities of CNC technology.

How CNC Machines Work

Exploring the inner workings of CNC machines uncovers a finely orchestrated sequence of precise movements and meticulous processes. The journey begins with design software, which crafts the initial digital model. From there, the process transitions to the CNC machinery, where these designs are transformed into commands through G-code. This specialized programming language meticulously guides every movement of the machine, ensuring that each cut and engraving is performed with impeccable precision.

Materials Suitable for CNC Machining

CNC machines demonstrate impressive versatility, able to shape a wide array of materials with precision. Commonly used metals such as aluminum and steel are favored for their durability and ease of machining. Plastics are chosen for their versatility and straightforward handling, whereas composite materials, which combine strength and lightness, are particularly suited for aerospace applications. Each type of material requires tailored approaches and specialized tools to optimize the cutting conditions and achieve the desired finishes.

Benefits of CNC Machining

The advantages of CNC machining are manifold. Its precision and reproducibility stand out, ensuring components are produced with consistent quality and exacting tolerances. Additionally, the speed and efficiency of CNC machines allow for quicker production cycles and significant cost reduction, particularly for high-volume or complex projects.

Getting Started with CNC Machining

For novices, venturing into CNC machining begins with selecting the right equipment. A comprehensive buyer’s guide can aid in navigating the myriad options available, from simple machines suitable for hobbyists to complex setups designed for industrial applications. Setting up a CNC machine involves careful installation and calibration, ensuring all components function in unison for optimal performance.

Common Challenges and Troubleshooting

Even in a field as advanced as CNC machining, operators may encounter technical challenges. Common issues range from software glitches to mechanical failures. Effective troubleshooting requires a deep understanding of the machinery’s mechanics and software, enabling quick identification and rectification of problems to minimize downtime and maintain productivity.

The Future of CNC Machining

Looking ahead, CNC machining is poised for transformative advancements. Artificial Intelligence and automation are set to further enhance the precision and capabilities of CNC systems. These innovations promise not only to increase efficiency but also to open new avenues for customization and complex designs that were once considered unattainable.